EI&C engineering and installation project

Erection of new ADC Building 91 for F. Hoffmann-La Roche Ltd in Basel, Switzerland

As one of the leading specialists in industrial automation of process plants, Penta-Electric has comprehensive experience in a wide range of industries – in Switzerland as well as abroad. This includes work in the pharmaceutical industry in particular. We’ll gladly accept any challenge head-on with our extensive expertise and experience, and prove to you that perfection is achievable.

Project description

The ADC91 project comprised construction of a new facility for production of antibody-drug conjugates (ADC) at the Roche site in Basel, Switzerland, between March 2014 and July 2016. The new building contains the production lines along with utility and laboratory spaces and auxiliary rooms.

The requirements specified by Roche

Overall project execution throughout all project phases:

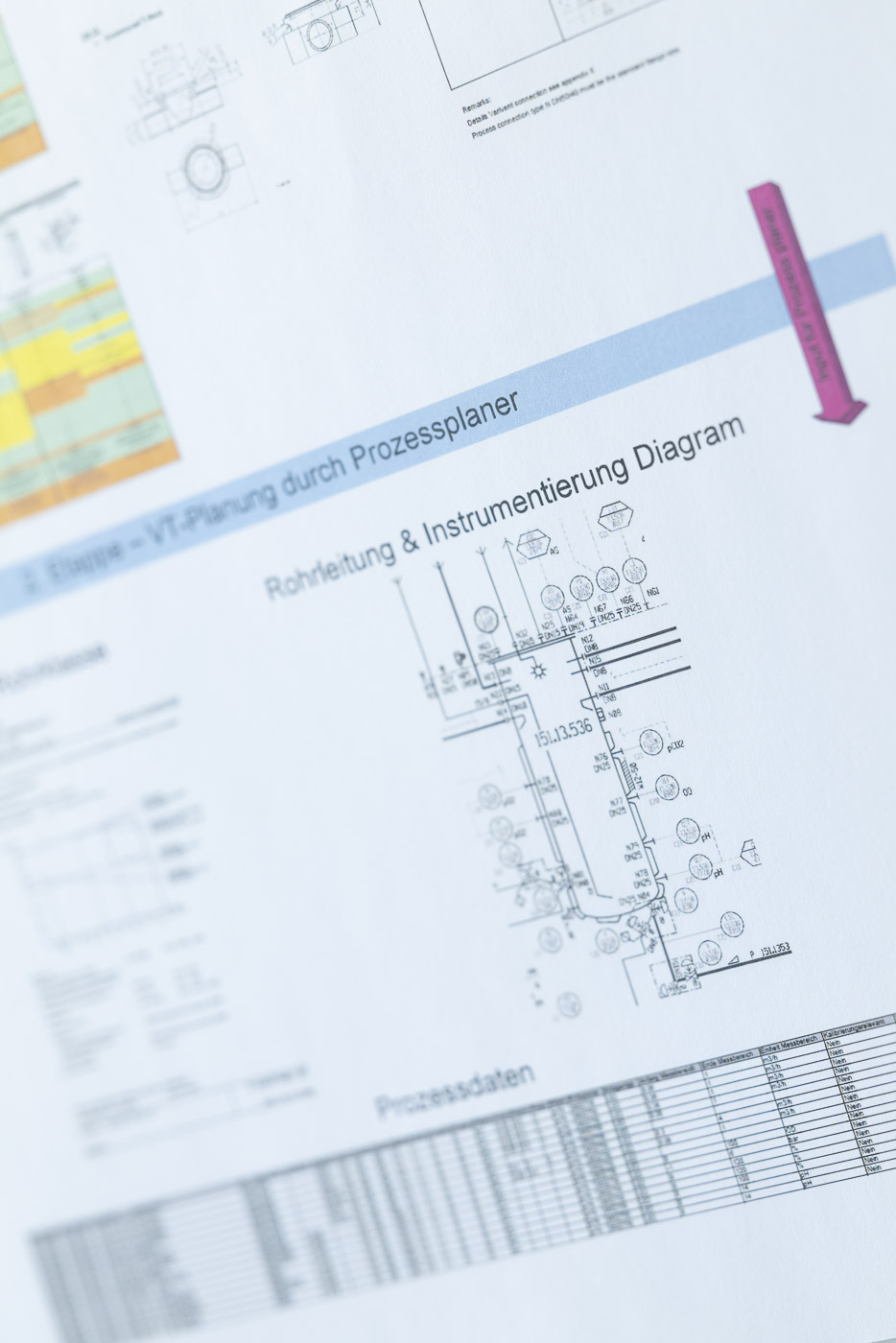

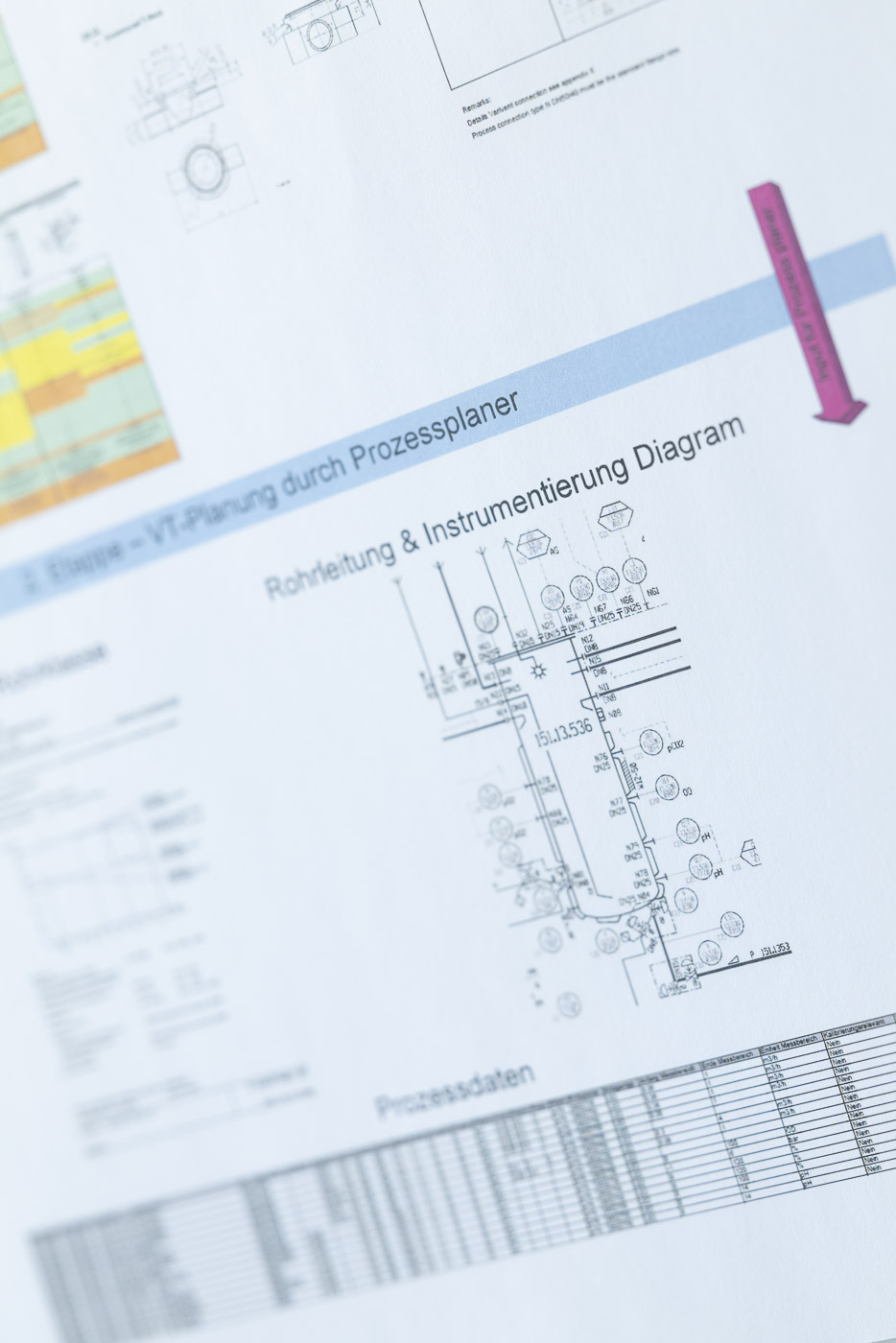

- Conceptual design of the electrical equipment and instrumentation and control (EI&C) hardware systems

- Layout planning (of electrical equipment rooms and cabinets, the control room and cable routing planning)

- Detailed planning of all circuit diagrams and position diagrams using the COMOS PT plant engineering software system

- Generating all equipment and instrumentation specifications (DFI data sheets)

- Coordinating the interfacing of package-unit suppliers

- Network planning (Ethernet, Profibus and Profinet)

- Performing computational design analyses (heat loss, short-circuit currents, selectivities, control air consumption)

- Generating tender specifications (for EI&C installation, EI&C rooms, equipment, operating stations)

- Supporting the procurement process

- Performing the on-site plant EI&C installation work

- Line testing and installation qualification

The custom-tailored solution from Penta-Electric

Uniform use of the COMOS data platform enabled consistent and virtually fault-free engineering from end to end. Our COMOS specialists in electrical, instrumentation and control engineering generated numerous documents in the form of lists and graphics to enable risk analyses, materials procurement and on-site installation.

The installation team was agilely adapted to the dynamic project conditions to achieve optimum efficiency in small, highly skilled teams of specialists.

The benefits for Roche

Contracting Penta-Electric to carry out the complete scope of EI&C supply and services reduced package interfacing to a minimum. Thanks to that decision and our broad range of expertise across all tasks involved, the project was executed very successfully for our customer. Our experienced, well-organized team closely collaborated with the customer’s project management, jointly leading to the project’s success.

The challenge for Penta-Electric

With an extremely tight time schedule to meet, all plant sections and components had to be processed in parallel, and the project phases executed in overlapping succession.

Switzerland:

Switzerland:  Germany:

Germany: